- What We Do

-

-

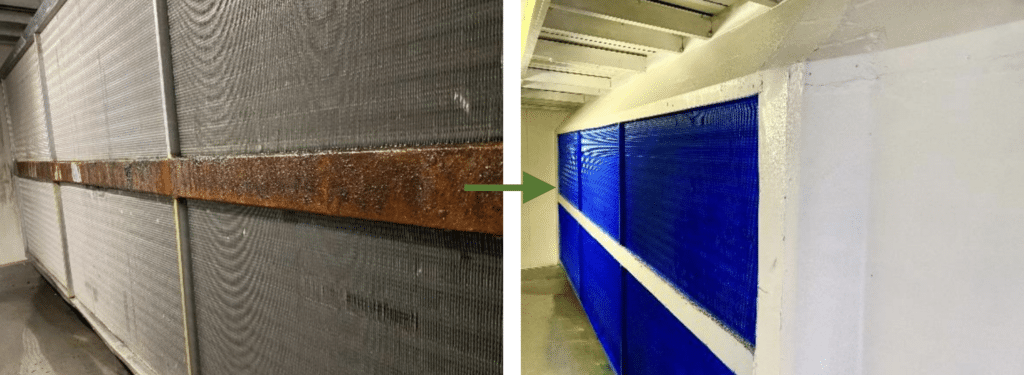

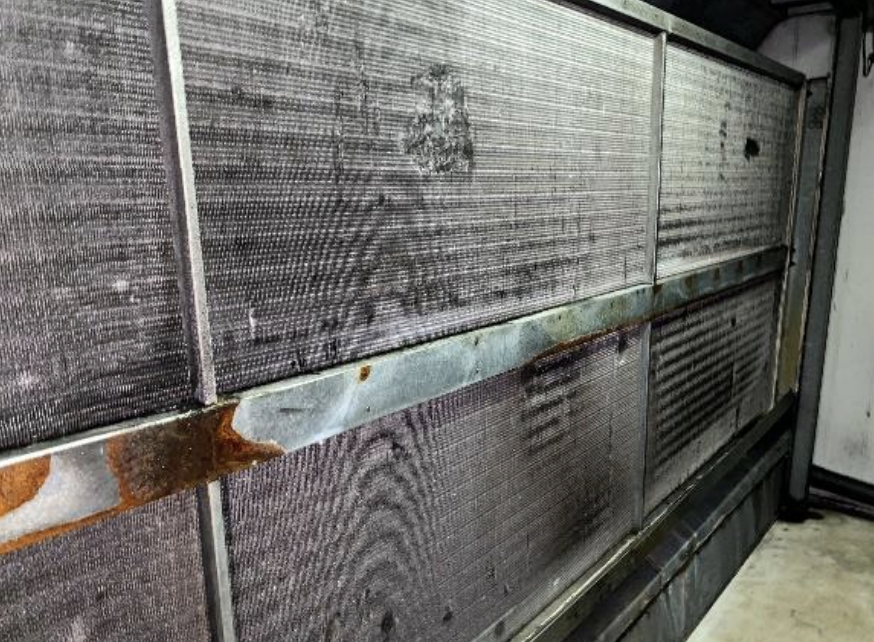

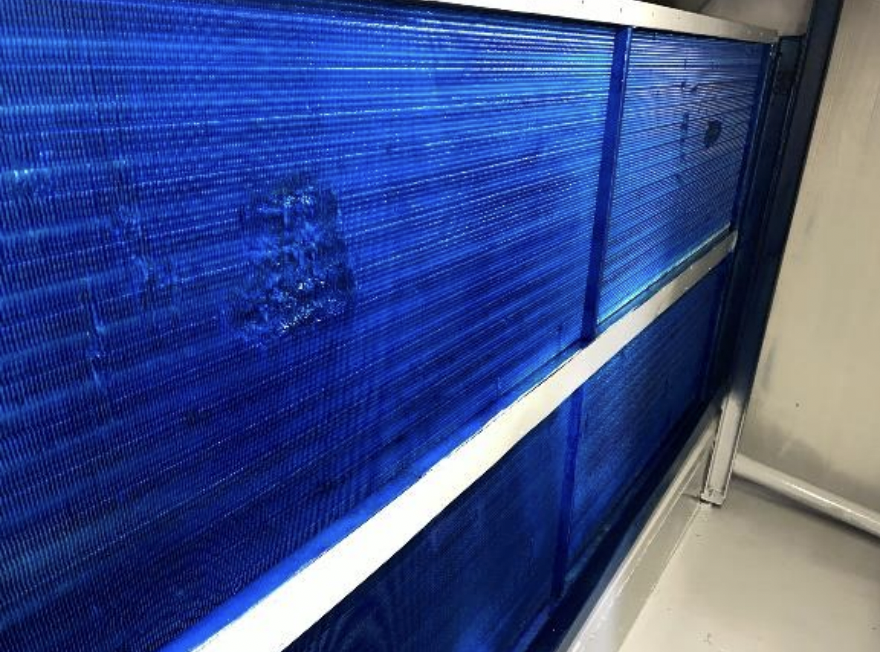

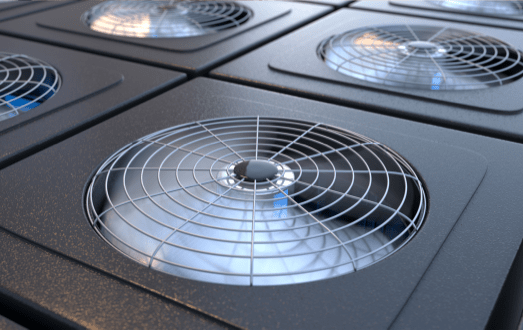

- We are Queensland’s premier HVAC cleaners, complying with all Australian standards.

-

-

-

- Who We Are

- Equipment Hire

- Locations

- Contact Us

Flood, water damage or Mould Issues? Mould Remediation & Moisture Assessments for homes and businesses – call now for a FREE quote: 1300 222 357